I have somehow earned the reputation for being good at making glass spirals.

It started when I was practising for the Meister exam. The man who would become my current boss, but who was back then my ‘coursework’ supervisor told the president of the German glassblowing society that I had a fascinating technique but produced good results.

He said he’d put me down to give a presentation during the seminar. I thought he was joking, but I was wrong..

I survived though, which is what counts I suppose.

A couple of weeks ago, one of the guys in our second company got a request for an apparatus involving spirals. The spirals consist of thin glass rods wrapped around (and melted onto) thickish glass tubes.

He asked me to make them for him.

The boss promised him I would, and then told me it was practically impossible to do, but that I should have a go because I’m “good at spirals “.

I spent a long time mostly avoiding the subject, besides, I had other things to do 😉 Trouble is, jobs like that don’t just go away. I practised a bit last week, and asked for some advice from a colleague at the other place I work.

Today, the boss decided they needed to be finished. He is driving over there tomorrow, and wanted/needed to take them with him.

Today was the day. Today I had to practise and produce sellable pieces.

Talk about pressure.

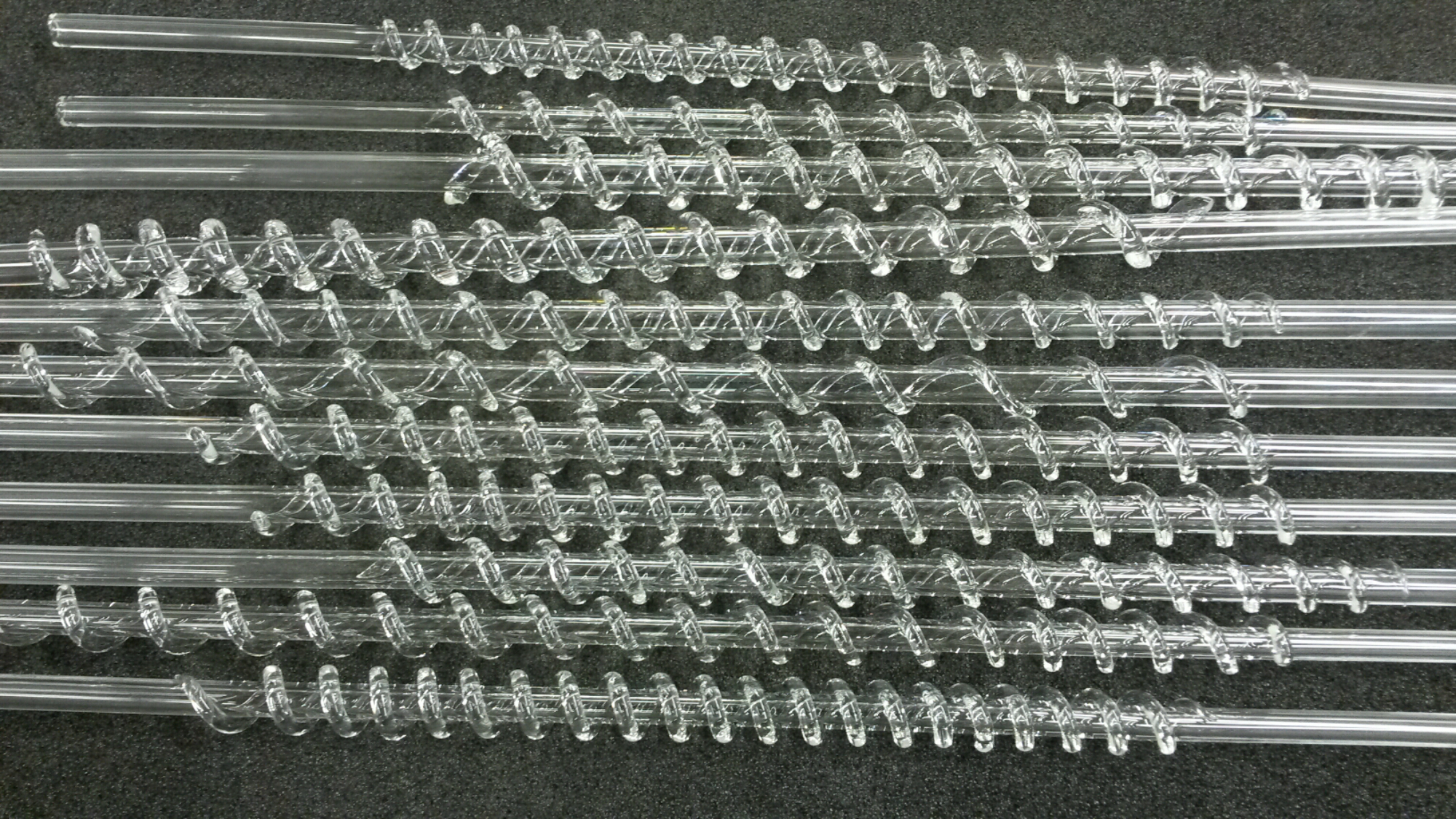

This is what I made:

The first 7 or so were dire. Either the spiral part splittered off the tube melted and went wonky 🙁

They aren’t perfect, but they’re sufficient.

I wrapped them up and the boss is going to take them to the other company tomorrow, where they will be tempered and built into a customer’s complicated project.

I hope they survive the night. Sometimes highly stressed pieces don’t and there’s not much more stressful than a melted on spiral…

Fantastic Job you did there. Very impressive. I can’t even melt a single rod into a round bead ?

Stop. That. Right. There.

The words ‘can’t even’ have no place on my blog. Not even in the comments. It’s the worst thing you can say, to yourself or to someone else. I know I’ve heard it enough and said it often enough about myself and it sucks. I hate the implication that whatever it is should be a given. It usually isn’t and often has no bearing on anything.

Rant over.

Thank you 🙂

A lot depends on the flame. It needs to be thin, a mixture of oxygen and air – not too hot, but which also doesn’t flicker too much. The rod needs to be almost too runny to hold steady, but not quite… The tube gets enough reflective heat, it doesn’t need any direct from the flame. Then you can turn the tube and roll the rod onto it, a bit like unravelling wool, only backwards 🙂

🙂 too complicated for me. I don’t get enough time to practice, and I only have a hothead torch. Haven’t done any glass for a least 6 months.

I also, have the almost irresistible urge to stick my fingers in a move the glass where I want it to go – so best to stick with the clay for me 🙂

Oh yeah, I get that urge too. Also the urge to bite it, but that’s probably just me….

well, it does look a bit like honey I guess. 🙂

Goodness! Do you know what on earth the project was that needed glass spirals? And what was it about your technique when you were training that was different enough that your supervisor found it fascinating?

The ones I was making last year /early this year are hollow, and used for cooling/condensing steam. These ones were like helterskelters for water droplets. There are 2 main ways to make spirals, either with the tube (to be wound) in front of you or behind you. Each method has advantages and disadvantages. Everyone who makes spirals has their own tricks when using the same basic method. I wind mine from left to right, my supervisor from right to left. I hold the tube over the flame, he holds his in the flame. I use more air, he uses more oxygen. The results are pretty much the same, but I can’t use his method and he can’t use mine. Does that make sense? It’s a bit like knitting. The stitches are the same, but everyone holds the needles differently (don’t get me started on how people wrap the wool round their fingers!)…

Beautiful! ?

Thankyou!